WESTLAKE

TAPPING MACHINE

Machine tapping defined as a flute designed with a geometry to direct the flow of chips out of the hole. Spiral-point tapping and Spiral-fluted tapping fit into this category. This change to the flute geometry improves tapping efficiency.

The main function of the tap is as a tool for making threads, repairing damaged threads, or enlarging threaded holes.

One of the tapping machine products that is well known for its quality is the WESTLAKE brand drilling machine, this product manufactured in China has proven its quality among dealers and users. because the machine is durable, strong and precise in it's performance.

| MODEL | SWJ-6A/12A | SWJ-16/16A |

| Max.tapping capacity (iron/steel) | M6/M5, M12/M8 | M16/M12 |

| Distance spindle axis to clomn surface | 127mm | 183mm |

| Max.distance spindle nose to worktable | 231/220mm | 492/450mm |

| Spindle travel | 40/45mm | 50mm |

| Spindle taper | B12/B16 | B18 |

| Spindle speed range | 480,850rpm/260-750rpm | 240-570rpm |

| 580, 1050rpm/320-930rpm | 275-650rpm | |

| Dimension of wortable surface | 230mm/245mm | 270x280/320mm |

| Overall height | 815/825mm | 1230mm |

| Motor | 370W | 750W |

| Gross weight | 63/43Kg | 120Kg |

| Net weight | 72/48Kg | 102Kg |

| Ship measurement | 61x44x93cm | 79x46x134cm |

Related Product

WESTLAKE

LIGHT TYPE BENCH DRILLING MACHINE

WESTLAKE

HIGH-SPEED ACCURACY DRILLING MACHINE

WESTLAKE

AUTO-FEED BENCH DRILLING MACHINE

WESTLAKE

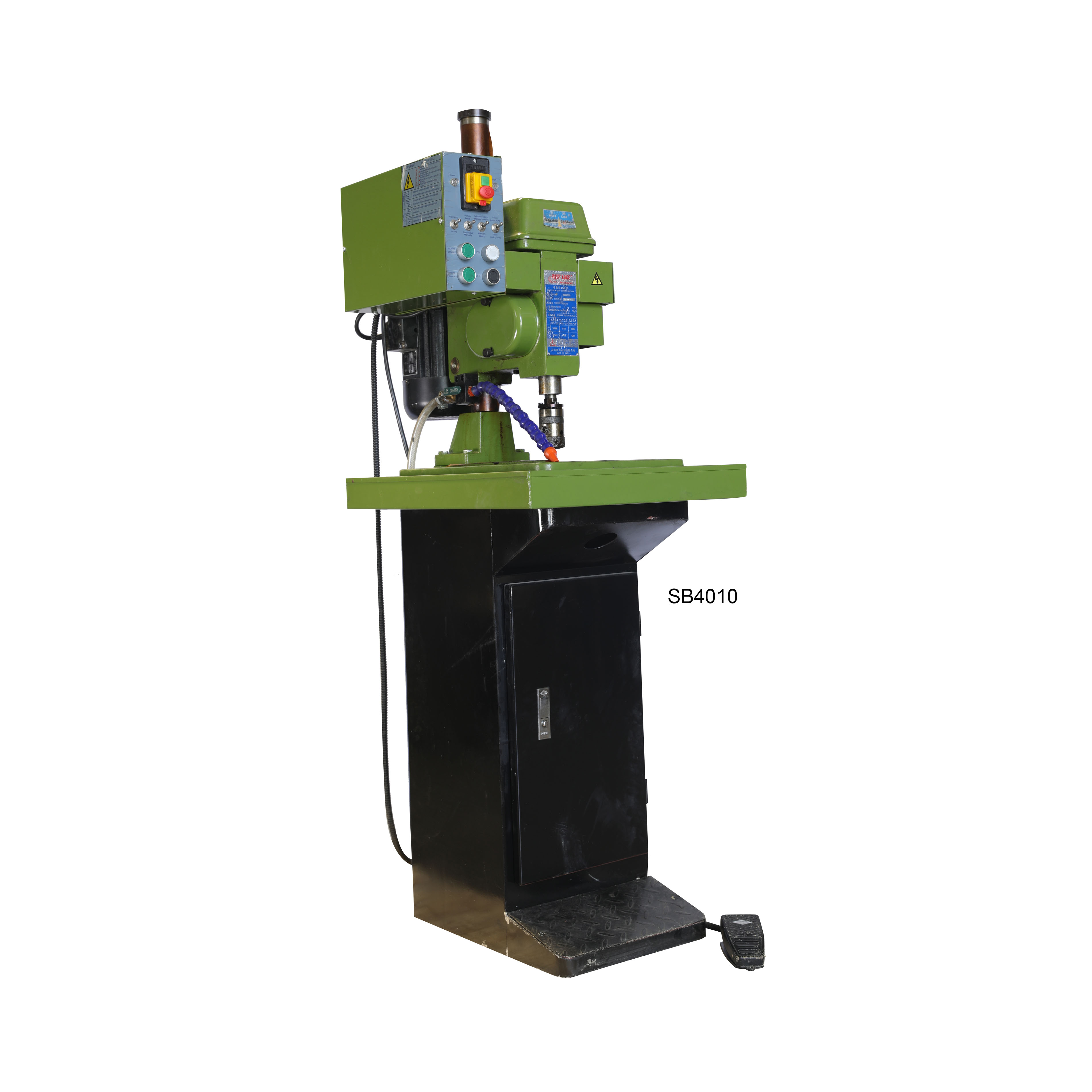

DRILLING AND TAPPING MACHINE

WESTLAKE

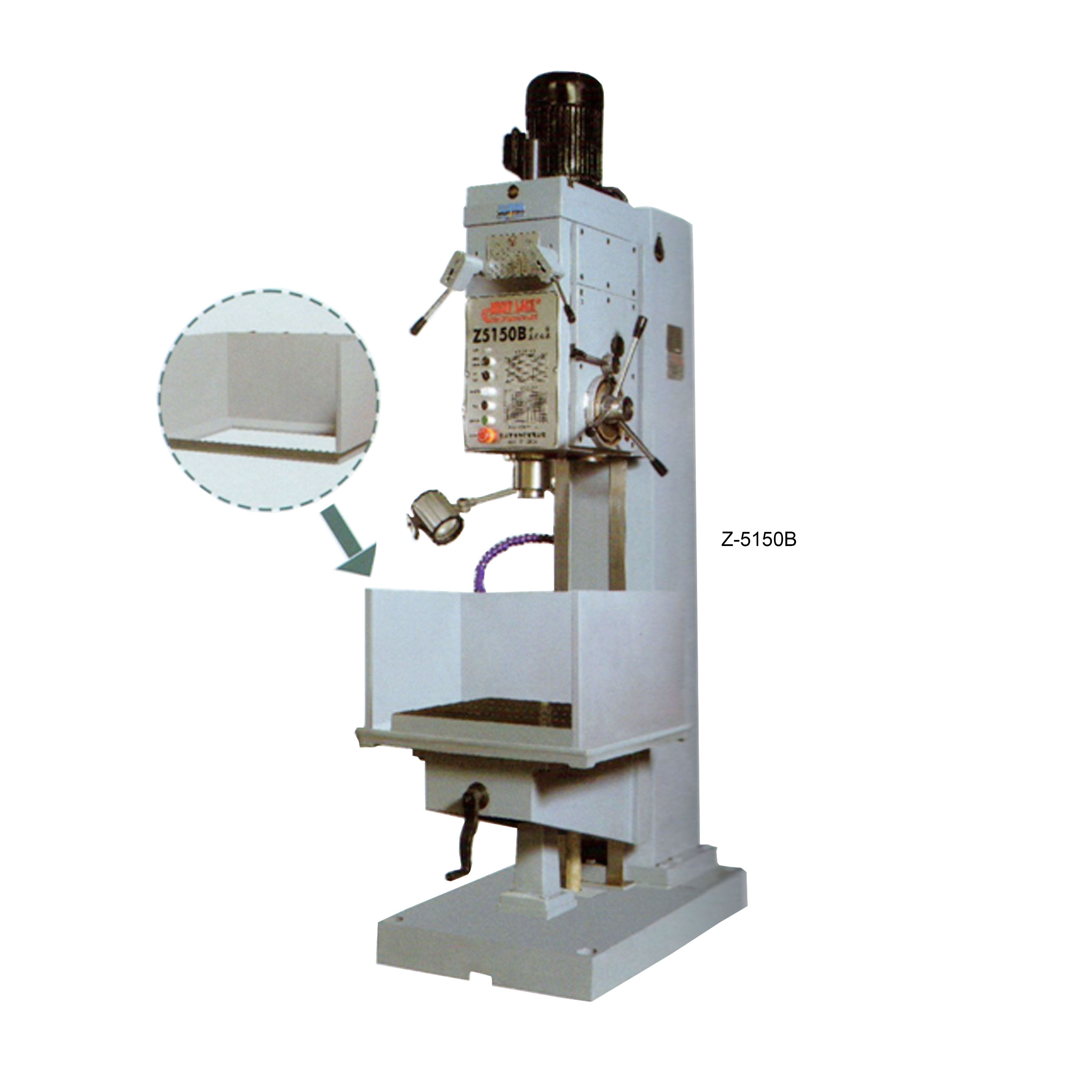

SQUARE UPRIGHT DRILLING MACHINE

WESTLAKE

MILLING AND DRILLING MACHINE

WESTLAKE

GEAR-PITCH TYPE AUTO TAPPING MACHINE

WESTLAKE

TAPPING MACHINE

WESTLAKE