MORRIS

WELDING MACHINE KLG PLASMA CUTTING SERIES

Plasma cutting is a machine that functions to cut various types of metal, plate or other materials using heat sourced from a high concentration laser beam where the depth level is adjusted according to the thickness of the material to be cut.

The basic principle of Plasma Cutting is to use electricity to heat the air very high up to the point of plasma (heat above thousands of degrees Celsius) which is then blown through the metal to be cut. Plasma Cutting Machines are very simple and only require a compressed air supply and AC power outlet to operate.

In the working process of the plasma cutting machine, an invert gas is blown at high speed from the nozzle, and at the same time an electric arc is formed through the gas from the nozzle to the surface to be cut, then some of the gas turns into hot plasma to melt the metal and move so that the metal cut off.

| MODEL | KLG-120 | KLG-160 | KLG-200 | KLG-300 |

| Voltage (V) | 380 | |||

| Rated input (KVA) | 42 | 48 | 60 | 90 |

| Frequency (Hz) | 50/60 | |||

| Phase | 3 | |||

| No-load voltage (V) | 240-300 | |||

| Output current range (A) | 140 | 160 | 200 | 300 |

| Rated output voltage (V) | 120-140 | |||

| Duty cycle (%) | 60 | |||

| Effeciency (%) | 85 | |||

| Air pressure (Mpa) | 0.2-0.3 | |||

| Max.cutting thickness (mm) | 40 | 50 | 65 | 80 |

| Weight (Kg) | 220 | 250 | 300 | 350 |

| Dimension (mm) | 1150x640x850 | 1300x750x1000 | ||

Related Product

MORRIS

WELDING MACHINE IGBT SERIES

MORRIS

WELDING MACHINE TIG SERIES

MORRIS

JET CLEANER

MORRIS

ANGLE GRINDER

MORRIS

DIESEL GENSET

MORRIS

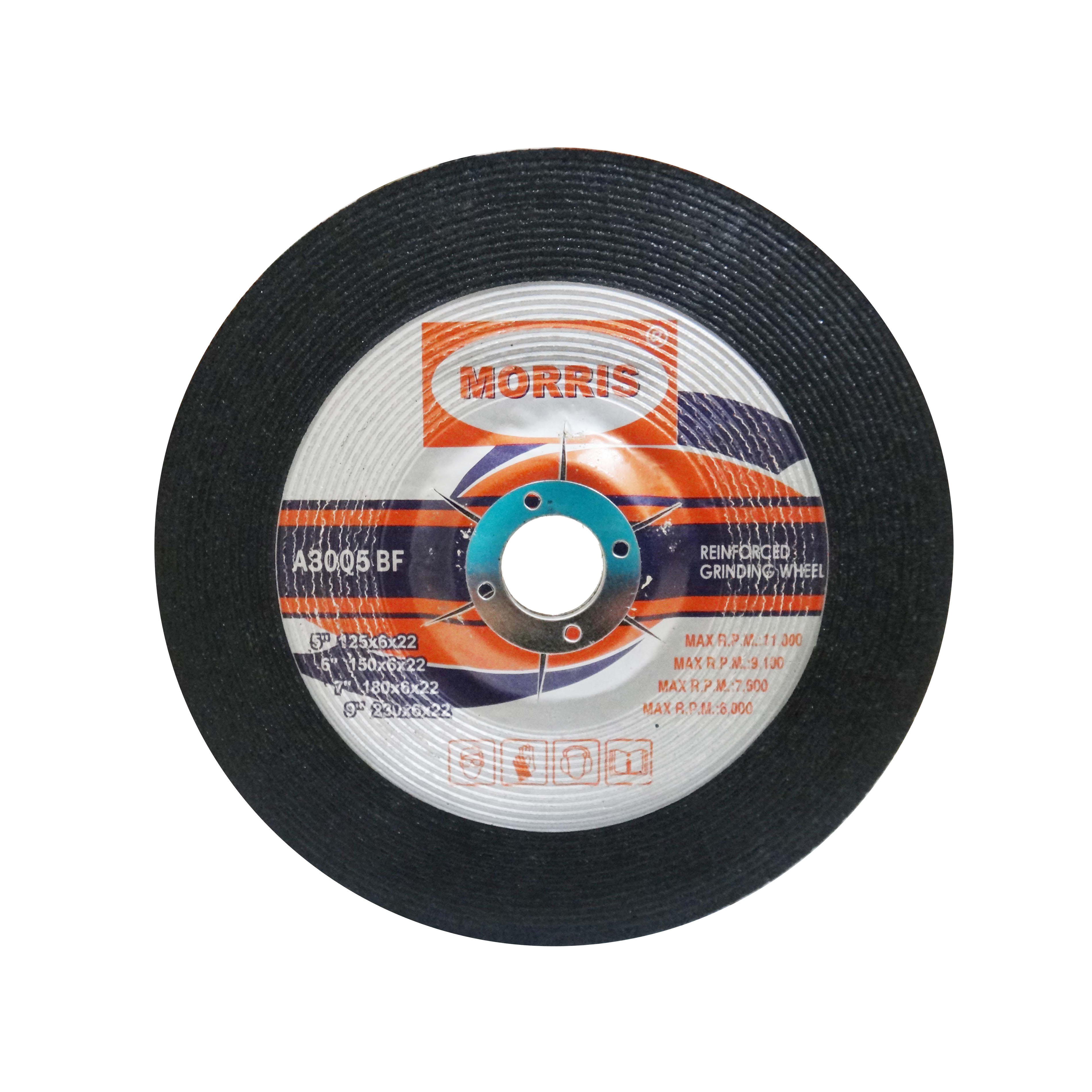

GRINDING WHEEL MORRIS A30Q5

MORRIS

CUT OFF WHEEL MORRIS

MORRIS

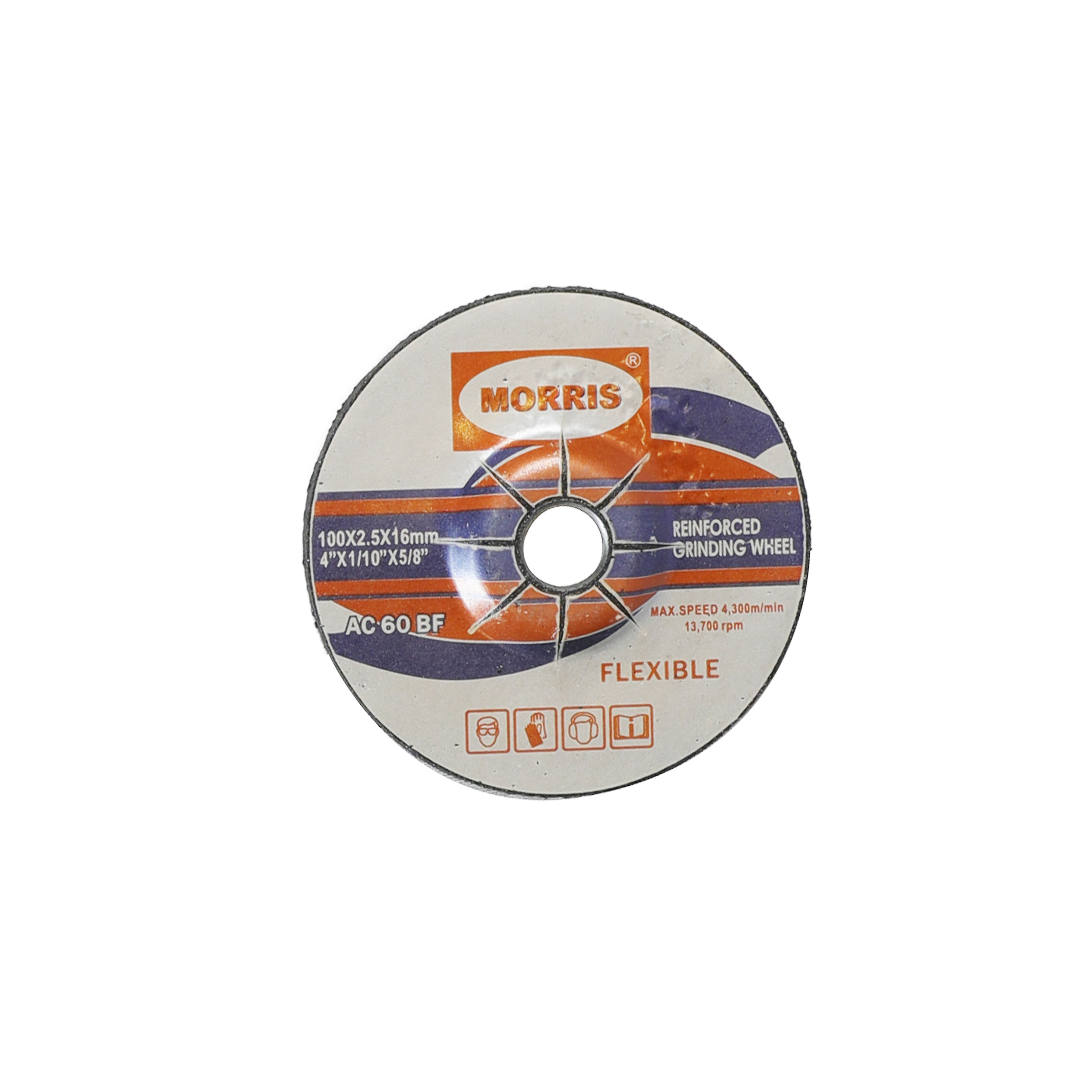

FLEXIBLE GRINDING WHEEL

MORRIS

FLAP DISC MORRIS

MORRIS

POLY DISC MORRIS

MORRIS

BRUSH CUTTER MBC 328

MORRIS

FLEXIBLE DUCT HOSE

MORRIS

TAMPING RAMMER MRM SERIES

MORRIS

FOGGING MACHINE MSM SERIES

MORRIS

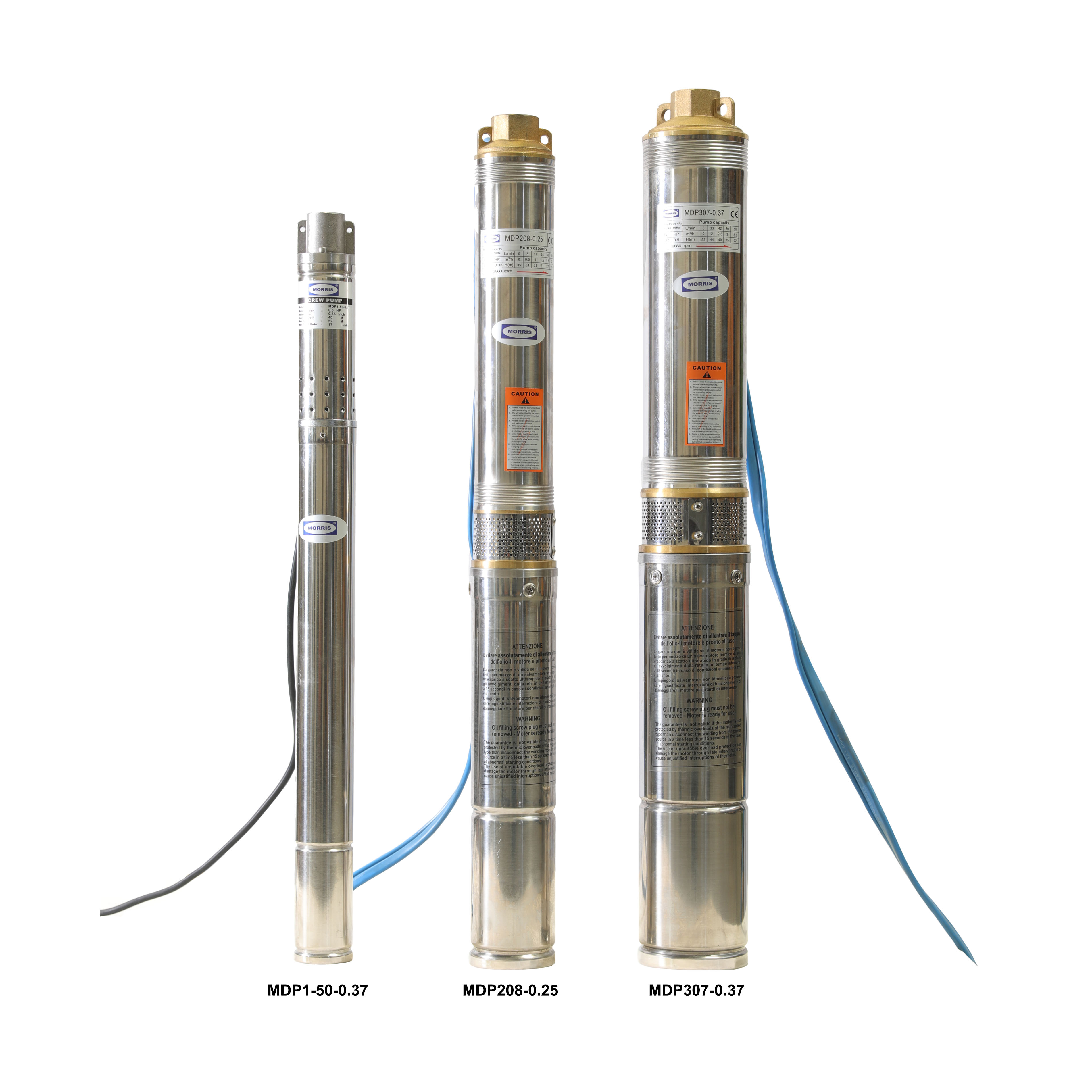

SATELLITE PUMP MDP SERIES

MORRIS

GASOLINE GENSET

MORRIS

GRINDING POLISHER

MORRIS

DIE GRINDER

MORRIS

BENCH GRINDER

MORRIS

ELECTRIC DRILL

MORRIS

CORDLESS DRILL

MORRIS

GASOLINE JACK HAMMER

MORRIS

ROTARY HAMMER

MORRIS

CORDLESS ROTARY HAMMER

MORRIS

DEMOLITION HAMMER

MORRIS

CUT OFF MACHINE

MORRIS

MITER SAW

MORRIS

CHAIN SAW

MORRIS

ELECTRIC CHAIN SAW

MORRIS

ELECTRIC SANDER

MORRIS

ELECTRIC PLANER

MORRIS

POLISHER

MORRIS

HEAT GUN

MORRIS

MAGNETIC DRILL

MORRIS

PORTABLE AIR COMPRESSOR

MORRIS

ENGINE SPRAYER

MORRIS

ELECTRIC SPRAYER

MORRIS

GUN SPRAYER

MORRIS

PORTABLE SMOKE SPRAYER

MORRIS

BOOSTER SPRAYER

MORRIS

VACUUM CLEANER

MORRIS

ELECTRO MOTOR MORRIS

MORRIS

WELDING ELECTRODES AWS 6013

MORRIS

JET CLEANER CARBON BRUSH

MORRIS

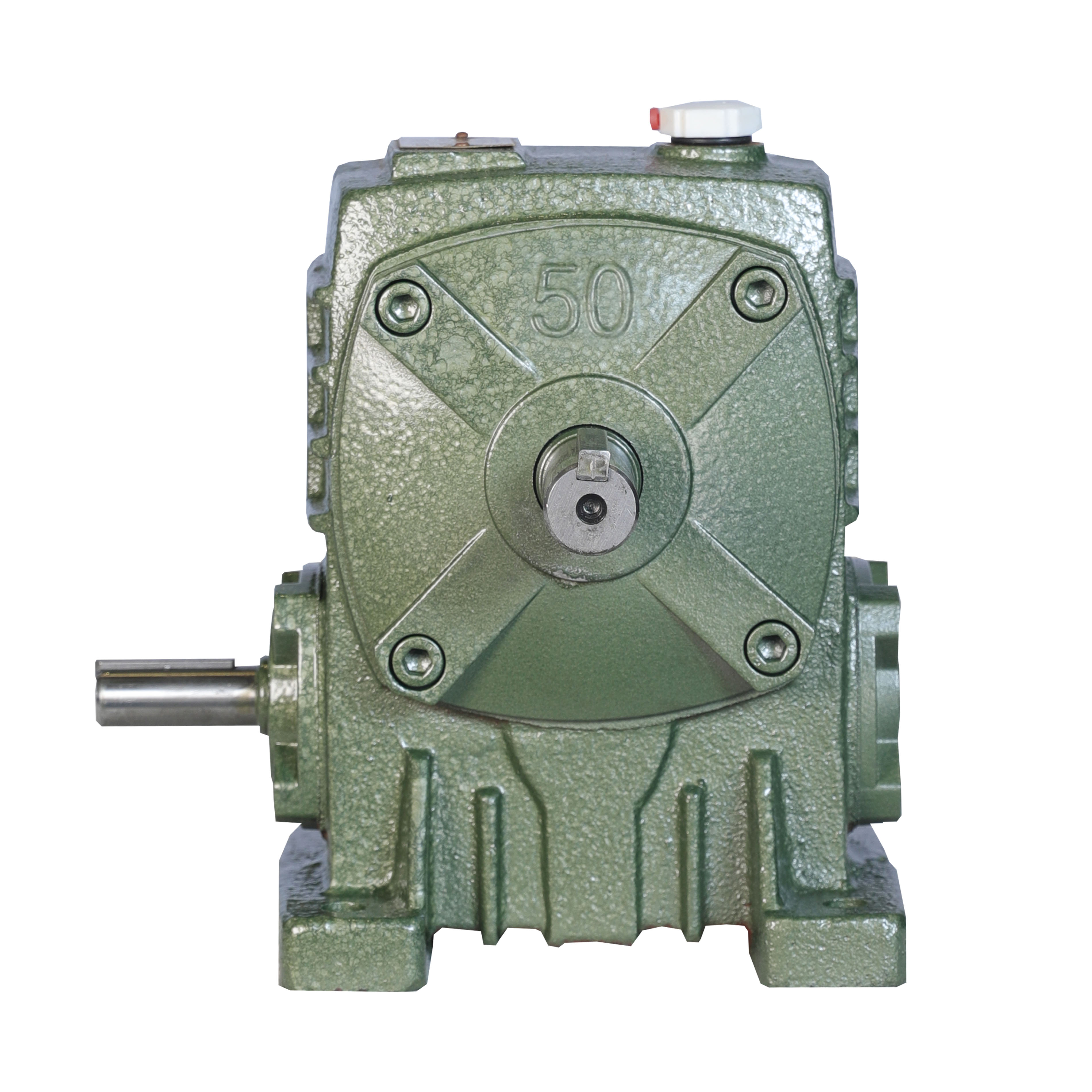

SPEED REDUCER FCA SERIES

MORRIS

SPEED REDUCER FCS SERIES

MORRIS

SPEED REDUCER FCX SERIES

MORRIS

SPEED REDUCER FCO SERIES

MORRIS

SPEED REDUCER NMRV SERIES

MORRIS

SPEED REDUCER FCL SERIES

MORRIS

CONCRETE CUTTER

MORRIS

POWER TROWEL

MORRIS

MOBILE LIGHT TOWER

MORRIS

PLATE COMPACTOR

MORRIS

CORDLESS DRILL MCD 107I

MORRIS

BRUSHLESS WRENCH

MORRIS

BRUSHLESS ANGLE GRINDER

MORRIS

BRUSHLESS CHAIN SAW

MORRIS

LAWN MOWER

MORRIS

CORDLESS GRASS TRIMMER

MORRIS

FLOOR POLISHER

MORRIS

KINGREX HACKSAW MACHINE

MORRIS

MANUAL ICE CRUSHER

MORRIS

ELECTRIC ICE CRUSHER

MORRIS

HAND MEAT MINCER

MORRIS

ALTERNATOR (FULL COPPER)

MORRIS

SEMI-ROTARY PUMP

MORRIS

GEAR PUMP RRC

MORRIS

AIR BLOWER RRC

MORRIS

WELDING TRANSFORMER BX1

MORRIS

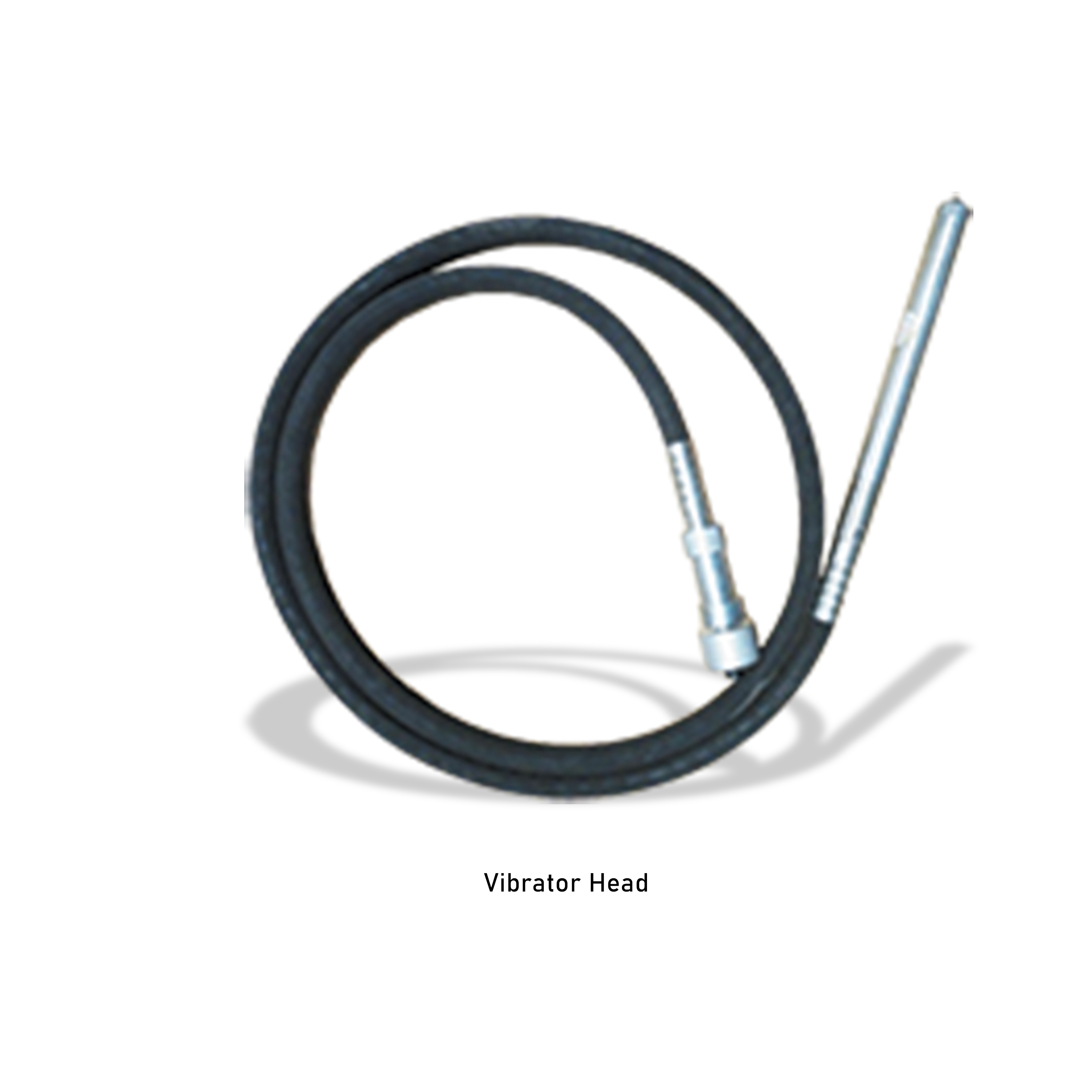

VIBRATOR HEAD

MORRIS

.jpg)